Industrial Hygiene Software

Assess Controls to Identify Hazards and Mitigate Risks

Promote a Safe and Healthy Workplace Through an Integrated, Comprehensive Industrial Hygiene Platform

Conducting risk

assessments, ensuring regulatory compliance requirements are met, and identifying effective hazard control measures are all critical for protecting employees’ health and safety. To accurately measure industrial hygiene-related risk levels, organizations must have a means of measuring risk and identifying the proper evaluation methods & controls.

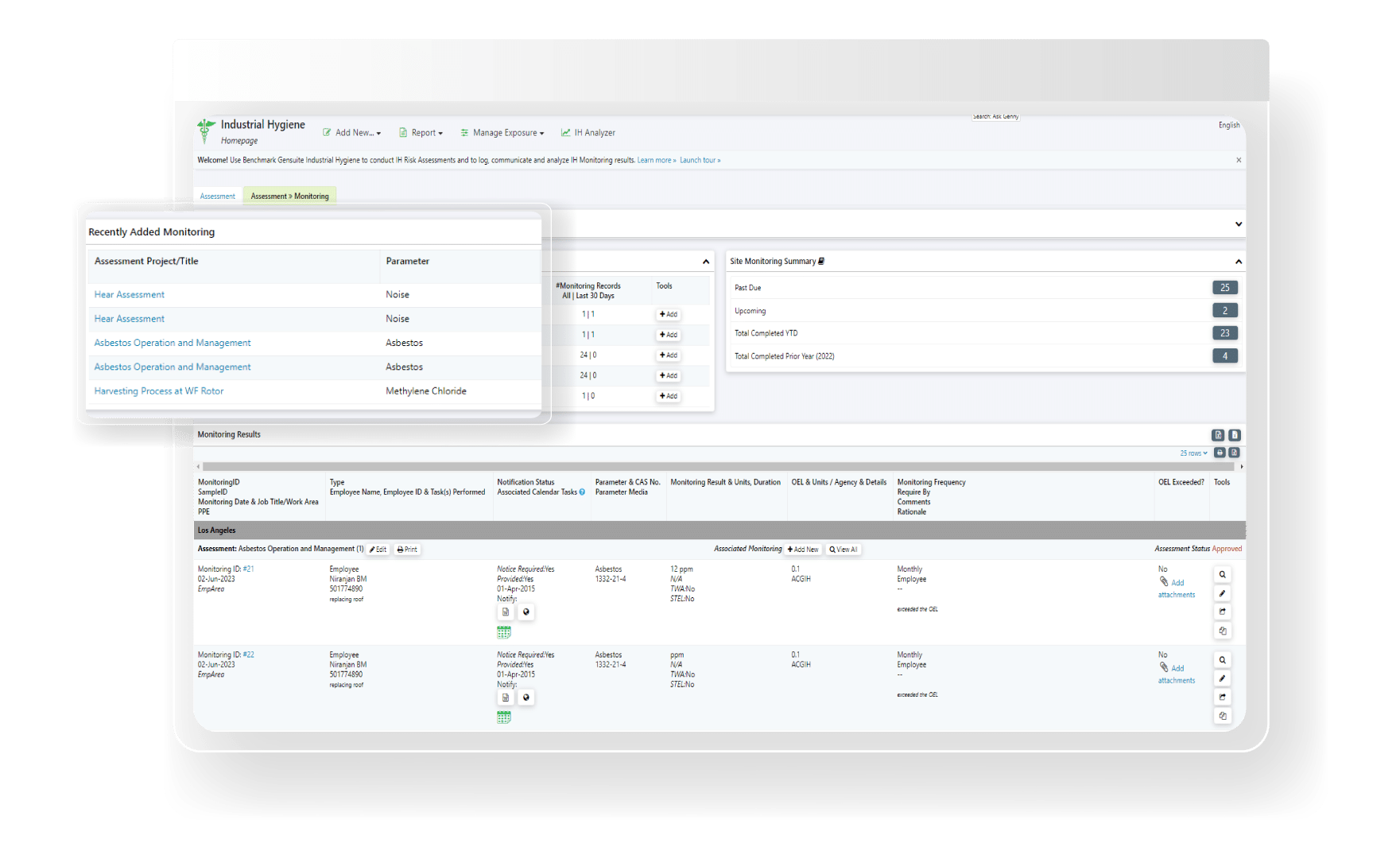

Benchmark Gensuite’s Industrial Hygiene software is built on best-practice-driven workflows and a cutting-edge cloud technology platform to digitally enable Occupational Hygiene management for a safer and healthier workplace. Establish a standardized process to conduct thorough risk assessments, identify appropriate controls, and compare against Occupational/Permissible Exposure Limits (OEL/PEL). You can also notify key stakeholders and employees of an area or personal assessment status and results, track monitoring record requirements and frequency for additional reviews, and have real-time reporting for more comprehensive program management.

Why Industrial Hygiene for Your Occupational Health & Industrial Hygiene Program?

Standardize Exposure Assessments:

Establish a standardized process for Industrial Hygiene exposure assessments across all site operations.

Consolidate Documentation:

Document qualitative Industrial Hygiene risk assessments with identified potential exposures and controls, prioritize follow-up, and document and analyze monitoring results.

Develop Insights:

Track and analyze Industrial Hygiene exposure assessments, monitoring summaries, and leverage automated occupational/personal exposure limits.

Heighten Safety:

Standardize and streamline IH programs by integrating risk assessments, monitoring results, and employee/supervisor notifications with the power of reporting, trending, and statistical analysis for a cohesive view of IH programs.

Integrate Seamlessly:

Schedule re-monitoring tasks with Compliance Calendar and search/access monitoring records by GPS coordinates using Mapper.

Learn how you can conduct industrial hygiene risk assessments and log, communicate, and analyze industrial hygiene monitoring results.

Features & Benefits

Minimize Hazardous Exposures to Protect Employees

Increase Program Visibility

Auto-generate email notifications to indicate status of IH assessments, site exceedances, and business summaries.

Identify Potential Industrial Hygiene Risks

Perform qualitative assessments with quantitative monitoring to understand potential risks and opportunities for reducing or mitigating risks.

Assess Industrial Hygiene Monitoring Data

Compare your organizational IH data with OELs/PELs and perform detailed statistical analysis to gauge performance and introduce improvements.

“The product evolution is profound and intuitive. There is not a single application that has not been thoughtfully designed, developed, and tested—all accompanied by detailed support and training materials.“

Take Your Program to the Next Level with Advanced Tech & AI

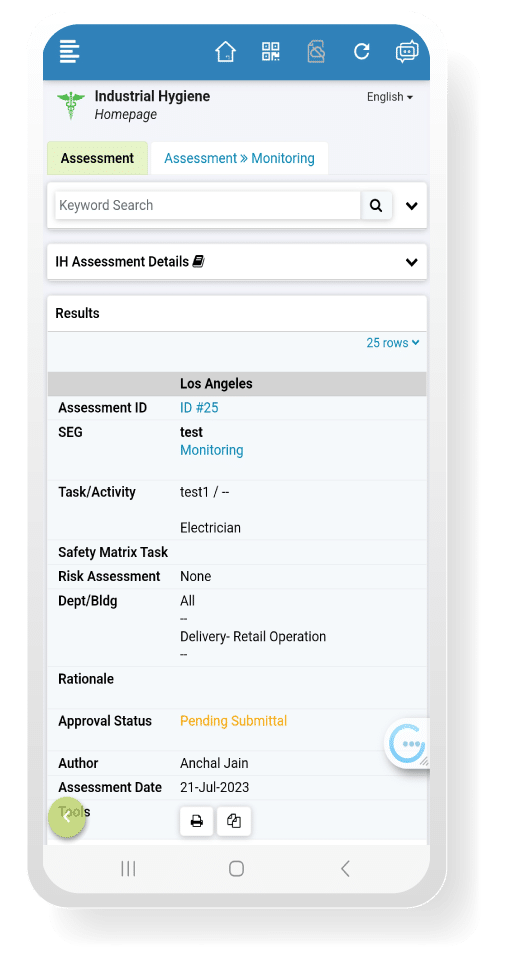

Benchmark Gensuite Mobile

Connect on the go for functionality and flexibility wherever work is— from the office to the field.

Dashboards & Analytics

Unlock the power of your data through robust visualizations & reports— powered by Tableau®.

ChemAdvisor™

Identify emerging chemical risks & toxicological impacts of the chemicals used across your operations— powered by Praedicat.

See What People are Saying

“EHS systems are going to be the systems of record that help your CEO, CFO, the entire finance function, respond to this huge deluge of requests for ESG data from the financial markets."

“Benchmark’s Product Steward solution simplified and removed the subjectivity from the supplier outreach process, enabling Amphenol to conduct seven different supplier outreach campaigns across 20K+ suppliers in 2020 –specifically targeting the “S” in ESG”

"The product evolution is profound and intuitive. There is not a single application that has not been thoughtfully designed, developed, and tested – all accompanied by detailed support and training materials."

Unlock the Full Power of our Occupational Health & Industrial Hygiene Solutions Suite

Join Our Over 3 Million Users Who Trust Our Occupational Health & Industrial Hygiene Software

Standardize Employee Occupational Health Data: Streamline IH assessments and standardize health clinic management.

Increase Visibility to Worker Care: Manage employee clinic visits and share data with teams.

Holistic Employee Health Management: Trak, monitor, & analyze employee health and IH.

Mitigate Health & Safety Risks: Complete corrective actions, and manage health training.